Contactless power supply

Continuous powering of rail-mounted conveyor applications and transportation systems.

Introduction

Power Rail is our system family for contactless power supply to systems with rail-mounted vehicles. This type of power supply is made for high-speed traveling over long distances, free from emissions, and suitable for wet and damp environments as well as water applications. The 85 kHz version offers even higher system efficiencies, smaller application sizes and lower system weights.

- Modular and suited for long-distance tracks

- Unlimited movements and high traveling speeds

- Withstands harsh and sensitive environments

Learn about how and where contactless power supply can be used

ENRX IPT Power Rail Datasheets: Essential specifications and features

Access the ENRX IPT Power Rail datasheets, offering sustainable, adaptable rail-mounted power solutions. It's designed for broad application versatility, emphasising durability, seamless integration, and low maintenance. It is ideal for enhancing operational efficiency sustainably, making it suitable for various demanding environments.

Projects

In worldwide operation since 1996 with more than 200.000 meters of continuously powered tracks in daily use.

Amusement park ride

- Walibi, Netherlands

- Power Rail

- 180 m system with 10 vehicles, 4 kW each

Electrified monorail system to transport auto chassis

- Mitsubishi, Australia

- Power Rail and iDAT

- 7 track supplies, 30 kW, 500 m total path length, 20 vehicles with 1.5 kW

Electrified monorail system in final assembly line

- KIA Motors, Slovak Republic

- Power Rail and iDAT

- 6 individual installations, 1500 m in total path length, 97 vehicles, each with 750 W or 1500 W

Inclined elevators in construction

- Docklands, Germany

- Power Rail

- Two elevators, each 60 m each with 1 mobile unit, supplied with 8 kW

Skillet system

- Hyundai Motors Manufacturing, Czech Republic

- Power Rail

- Electrification of push-plate lifting tables, two tracks, each 245 m, total 88 e-pickups 4 kW

Sorting facility in mail-order house

- Carrefour, France

- Power Rail

- Track supply 10 kW, 160 m total path length

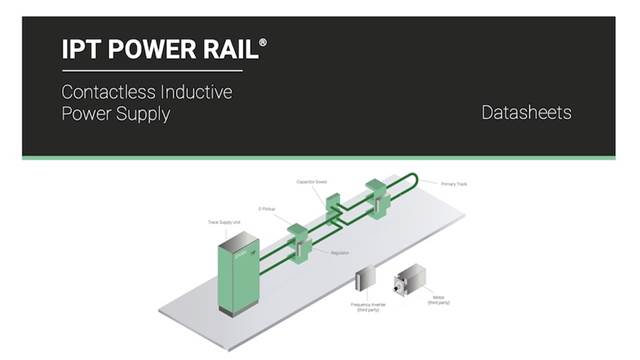

Example of Power Rail Installation

Stationary components

- Track Supply Unit 20 kHz

- Track Power Supply Unit 85 kHz

- Capacitor Boxes

- Litz Cable

- Intelligent components for ease of installation

Mobile components

- F-Pickup/Regulator 20 kHz

- E-Pickup/Regulator 85 kHz

- iDAT position measuring